What Is Crystal And What Is It Made Of?

Crystal Ingredients

Crystal is made of silica, sodium carbonate and calcium carbonate or more commonly known as sand, soda ash, and limestone. Soda ash is added to the sand in order to lower the melting point and limestone is added to increase crystal's strength and durability. The raw materials are melted in a furnace at extremely high temperature of 1600 degrees.

24% Lead Crystal

Traditionally, crystal was made with addition of lead. The most prized lead crystal contains 24 percent lead oxide which provides the optimum weight, hardness and colour.

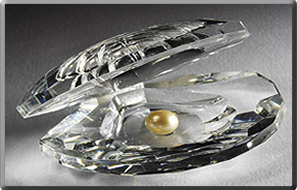

The addition of lead oxide makes crystal softer than glass and allows crystal artisans to cut and bevel lead crystal with brilliant edges. Because of its softness lead crystal can be poured into moulds and used in sculptural components of awards and trophies. Lead crystal is also widely used in production of fine crystal gifts such as vases, bowls and bar wear.

Optic Crystal - the ultimate in clarity and brilliance

Optic crystal is used in awards and trophies pieces and is 100 % lead free. The absence of lead makes optic crystal extremely hard. Because of its hardness we can polish crystal to flawlessly smooth surfaces as well as cut it and bevel it with brilliant edges.

Optic crystal is produced in sheets of molten material up to three inches thick and before it hardens is subjected to extreme pressure to remove any air bubbles, inclusions or flaws. Optic crystal is then polished, cut and bevelled by hand with ultimate skill and precision.

Crystal without lead is not any less valuable than full lead crystal particularly when it is thick and heavy and finely designed. In fact, clear uncut crystal has to be particularly fine quality because the flaws can not be hidden by the cuts. Using optic crystal in our awards manifests the ultimate recognition of excellence and appreciation. Crystal, with its exceptionally high perceived value, has been sought after and treasured for generations, and remains a status symbol even today.

Crystal Craftsmanship and Techniques

Engraving is the process of cutting into the surface of an annealed glass object either by holding it against a rotating copper wheel fed with an abrasive or by scratching it, usually with a diamond.

Carving is the removal of crystal from the surface of an object by means of hand-held tools. Cutting is the technique whereby crystal is removed from the surface of an object by grinding it with a rotating wheel made of stone, wood, or metal, and an abrasive suspended in liquid as the cutter holds the object against the upper, or top, side of the rotating wheel. Sand-blasting or Deep etching is an engraving technique which allows logo and text to be reproduced on crystal awards with great precision.

A design is transferred to a stencil and attached to crystal with special adhesives. Then abrasive sand is blasted to the stencilled award area at an optimised pressure. The design is permanently engraved into crystal with beautiful deep grooves. Hand cut crystal means the item is held against a spinning stone to cut the design. It is truly artistic workmanship at its best, which requires decades of experience!

Art Glass

Another popular trend is incorporating ART GLASS components into a piece of Crystal .Art glass production is characterized by experimentation with various materials that create impressive artistic effects. It takes great skill and precision to create art glass components for they are made individually by hand and by most accomplished glass artists.

Each art glass piece is a unique creation; thus sizes, colours, translucency grade vary from piece to piece. During the process of hand moulding small air bubbles and other colour particles may get trapped inside the glass. This is characteristic of art glass and by no means a defect. Air bubbles and material particles add character and uniqueness to art glass awards.